Business

OPPO Reno 7: OPPO’s End-to-End Quality Assurance Promise

OPPO Reno 7: OPPO’s End-to-End Quality Assurance Promise

Many factors influence a consumer’s decision to purchase a smartphone: the number of smart high-tech features, the phone’s stylish design, or its compact size.

However, if there is one element that can completely turn someone into a loyal fan of a brand, it has to be product quality. With tens of millions of users around the world, OPPO has built its reputation on strict end-to-end quality controls, covering everything from design and manufacturing to quality inspection and after-sales services. These processes are based on a relentless pursuit of attaining the high quality in both product and service, ultimately giving users comprehensive assurance when purchasing a product.

Excellent quality begins with excellent manufacturing

Selecting the world’s top suppliers to guarantee quality from the ground up

OPPO has been actively working with suppliers throughout the industry to create a wide ecosystem of partners. To supply the components that make up the smartphones, OPPO works with many leaders in their respective fields. Take the screen module for example: OPPO partners with Samsung Electronics, Japan Display Inc (JDI), BOE, Tianma Microelectronics, and other manufacturers known for producing top-quality displays and components. OPPO has been working closely with renowned glass suppliers such as Corning and SCHOTT to produce protective screen glass. By partnering with the top suppliers, OPPO is able to manufacture the precisely customized, high-quality components needed to ensure the quality of its end products from the most fundamental level.

Dedicated production lines/factories guarantee the highest standards

To further guarantee the quality of products that come off the production line, OPPO works with its partners to establish dedicated support teams, specialized production lines, and even specialized factories exclusively for OPPO. All components destined for use in OPPO products must be produced in these facilities, which are maintained to the highest standards in the industry. Every worker must undergo OPPO’s extensive pre-work training, including familiarization with OPPO technical documents, and having OPPO technical requirements embedded into the facility’s internal manufacturing processes. Design specifications and quality control procedures are taught to staff, and all production lines are operated by OPPO’s high standard.

Strict production environments also demonstrate OPPO’s precise control over the production line: OPPO requires its suppliers to construct highly intelligent production lines capable of standardized production. Each production line must be strictly certified and monitored, and every item is given a unique ID number to ensure that each tiny procedure can be traced back through the entire production process. When manufacturing smartphone displays for example, all displays are assembled in a Class 1000 dust-free cleanroom that meets more than 270 specifications to ensure standardized production. The production of each component is strictly controlled within fixed specifications to guarantee that every mobile phone provides the same flawless quality.

Rigorous process controls

Even if a smartphone is manufactured according to rigorous production methods, the device needs to be tested before it reaches the market. All OPPO products are required to pass quality and reliability verification on their components, production lines and complete devices. Further to this, independent quality controls are carried out across the entire manufacturing process, including pre- and post-assembly, installation, and completed device stages. If a potential quality risk is detected at any point, OPPO will reject the device, send it back to the manufacturing stage, and solve the underlying issue. Aside from checks performed during manufacturing, engineers and technical experts also conduct five rounds of comprehensive quality assessments and reviews. These include evaluations during products planning, design, development, and verification. If a smartphone fails during any round, it is not allowed onto the market.

Innovation based on assured quality

As a famous saying at OPPO goes “product quality comes from good design”. Part of the role of OPPO’s R&D personnel involves taking specific user needs and transforming them into higher quality user experiences through tailored product design. Good product design is more than just appearances – it requires guaranteeing that every feature and every aspect of the device delivers on its promise to users.

Dedicated designs make every promise a reality

Production feasibility needs to be taken into account from the very outset if design innovations are to perform as intended. OPPO product designers therefore need to create clear and detailed product blueprints with enough information for factory workers to understand and follow accurately. This requires product designers to think ahead during the product planning stage to consider problems that might be encountered during production and manufacturing, and then come up with detailed solutions before the designs are put into production.

Practical and durable process innovation

Not every imaginative design idea makes its way onto the smartphones. OPPO takes a very cautious approach to commercializing new designs. A novel design requires hundreds, or even thousands of trials, including material selection, testing of the manufacturing process, quality verification, or months of technical testing before it is brought to consumers on a finished smartphone.

Take the new Reno7 Sunset Orange for example. In order to give the back cover of the phone an expressive textured effect that also feels smooth in the user’s hand, OPPO designers examined thousands of different textures. Eventually, the team of designers narrowed down thousands of potential materials to just six options. Further market research on these six textures finally led to the selection of a lychee grain leather texture, chosen for its suitable thickness and natural, skin-friendly touch.

The designers then came across another new challenge when attempting to bring the exact textural effect to the back cover of the smartphone. To solve this, OPPO devised its own innovative Fiberglass-Leather made up of a synthetic leather material and a plate combined into one integrated piece designed to perfectly fit the shape of the phone. Compared with traditional leather covering processes, the Fiberglass-Leather design introduces a “frameless battery cover”, meaning that no plastic mid-frame support is required. This new leather and fiberglass construction results in a lighter, thinner, and more integrated back cover without compromising on practicality and durability.

Such innovations in design require further exploration in new applications of technologies and materials. To bring the appearance of high-quality leather to the Reno7 series, OPPO tested and modified ten different polyurethane materials and six bridging layers, and made five modifications to the glass fiber epoxy resin. To ensure the material could withstand up to 100°C heat and 1.5mPa of pressure for 4 hours during the manufacturing process, OPPO engineers strengthened the temperature resistance of the leather polyurethane material to 190°C and increase its tensile strength to 20mPa, ensuring that the material’s appearance did not warp during production. Together, these steps make it possible for the leather back cover to be mass produced at the desired level of quality.

Stringent testing of every detail

After the design and manufacture stages, more testing is required to fully guarantee that the finished product meets OPPO’s high standards before it arrives on the market.

Global test centers provide professional quality assessment

OPPO has established quality testing centers in China, India, and Indonesia, a professional quality team made up of hundreds of engineers and technical experts. OPPO’s quality laboratory has even been accredited by authorities such as the China National Accreditation Service for Conformity Assessment. In these quality testing centers, products need to pass more than 130 ultra-rigorous reliability tests, 320 experimental tests, and 6 major tests before they are ready for the next stage.

Comprehensive general testing goes beyond industry standards

OPPO products are only deemed fit for consumers if they have successfully passed a series of rigorous quality tests. These cover all day-to-day usage scenarios that the phone is likely to come across, including waterproofing tests, temperature and humidity tests, drop tests, RF tests, audio tests, radiation tests, battery tests, button pressing tests, plugging tests, twisting tests, light aging tests, cosmetics tests, extreme environment tests, clothing tests, and many more. To guarantee the same high quality for users around the world, some of these tests have much higher requirements than the industry average. For example, the drop test, which simulates a typical free-fall scenario from various heights, was set at a height of 1 meter for OPPO phones against an industry average of 0.8 meters. These comprehensive, demanding tests ensure OPPO devices can be used as expected in both regular and extreme environments.

Specific tests for special quality control

Apart from tests designed to ensure regular performance and functionality, OPPO also conducts specific tests to ensure the durability and practicality of innovative features or design elements. For instance, the Fiberglass-Leather on Reno7 Sunset Orange has been subjected to extreme lab tests involving rubbing the material with an alcohol-soaked pad, a rubber eraser, and a denim swatch over 5,000, 10,000, and 200,000 times respectively. By simulating daily wear and tear in this way, OPPO ensure that its innovative designs are durable and resistant enough to meet its high standards.

This same insistence on excellence can also be found in the high level of quality control around design details. The Orbit Light, which surrounds or embedded in the camera module on certain smartphone models, OPPO conducted over twenty uniform light scheme adjustments, thousands of uniform light detection tests, and other special tests. In the standard test environment (25°C, 60% humidity, 10mAh), the lifespan of the Orbit Light was shown to reach over 50,000 hours. Through these special quality control tests, OPPO can ensure that even the smallest of innovations deliver a reliable, fault-free experience.

Quality assurance from start to finish

To deal with issues caused by minor accidents during daily use, OPPO has established professional and friendly after-sales teams worldwide to provide services to every OPPO user, making up the final link in OPPO’s end-to-end quality assurance.

Following the opening of the first service center in Lagos Nigeria, OPPO began to rapidly rollout more centers nationwide. As of 2021, OPPO has established more than after-sales centers in Nigeria and regions such as Lagos, Abuja, Porthacourt, Ibadan, together, more than 100 customer service representatives work in these service centers.

Through these after-sales service centers, OPPO has built up a high-quality service model based on its Care & Reach philosophy. Through Care & Reach, OPPO brings customers industry-leading after-sales services based on three core values: Friendly Service, Professional Service, and Inspiring Service. For example, OPPO has introduced “1 Hour Flash Fix”and “Send-in Repair services”, making it possible for users to have their smartphones repaired quickly and efficiently. At the same time, these user-friendly services enable OPPO technical engineers to improve their troubleshooting skills and efficiency, helping them to provide faster, more convenient, and more professional services at all times.

Product quality can be very difficult to prove when it comes to complex devices such as smartphones. It is not until something goes wrong that an individual starts to question its quality. Therefore, OPPO bases its quality standard not on the results of factory testing but on direct feedback from the market. This includes things such as the maintenance rate for a certain device, and the product withdrawal rate.

Thanks to OPPO’s high quality requirements and rigorous quality control, failure rates for OPPO products available on the market are far below those of the industry average. For example, the failure rate from water damage is far lower than the industry average; products are also less likely to result in severe damage after being dropped and are more reliable when used in very humid climates or other extreme environments. Building upon this success, OPPO will continue to make quality a cornerstone of its commitment to consumers, bringing users reliable products and high-quality services through its end-to-end quality assurance program.

Business

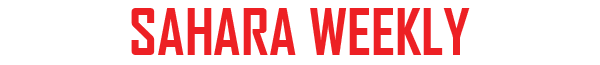

Nigeria’s Inflation Drops to 15.10% as NBS Reports Deflationary Trend

Nigeria’s headline inflation rate declined to 15.10 per cent in January 2026, marking a significant drop from 27.61 per cent recorded in January 2025, according to the latest Consumer Price Index (CPI) report released by the National Bureau of Statistics.

The report also showed that month-on-month inflation recorded a deflationary trend of –2.88 per cent, representing a 3.42 percentage-point decrease compared to December 2025. Analysts say the development signals easing price pressures across key sectors of the economy.

Food inflation stood at 8.89 per cent year-on-year, down from 29.63 per cent in January 2025. On a month-on-month basis, food prices declined by 6.02 per cent, reflecting lower costs in several staple commodities.

The data suggests a sustained downward trajectory in inflation over the past 12 months, pointing to improving macroeconomic stability.

The administration of President Bola Ahmed Tinubu has consistently attributed recent economic adjustments to ongoing fiscal and monetary reforms aimed at stabilising prices, boosting agricultural output, and strengthening domestic supply chains.

Economic analysts note that while the latest figures indicate progress, sustaining the downward trend will depend on continued policy discipline, exchange rate stability, and improvements in food production and distribution.

The January report provides one of the clearest indications yet that inflationary pressures, which surged in early 2025, may be moderating.

Bank

Alpha Morgan to Host 19th Economic Review Webinar

Alpha Morgan to Host 19th Economic Review Webinar

In an economy shaped by constant shifts, the edge often belongs to those with the right information.

On Wednesday, February 25, 2026, Alpha Morgan Bank will host the 19th edition of its Economic Review Webinar, a high-level thought leadership session designed to equip businesses, investors, and individuals with timely financial and economic insight.

The session, which will hold live on Zoom at 10:00am WAT and will feature economist Bismarck Rewane, who will examine the key signals influencing Nigeria’s economic direction in 2026, including policy trends, market movements, and global developments shaping the local landscape.

With a consistent track record of delivering clarity in uncertain times, the Alpha Morgan Economic Review continues to provide practical context for decision-making in a dynamic environment.

Registration for the 19th Alpha Morgan Economic Review is free and can be completed via https://bit.ly/registeramerseries19

It is a bi-monthly platform that is open to the public and is held virtually.

Visit www.alphamorganbank to know more.

Business

GTBank Launches Quick Airtime Loan at 2.95%

GTBank Launches Quick Airtime Loan at 2.95%

Guaranty Trust Bank Ltd (GTBank), the flagship banking franchise of GTCO Plc, Africa’s leading financial services group, today announced the launch of Quick Airtime Loan, an innovative digital solution that gives customers instant access to airtime when they run out of call credit and have limited funds in their bank accounts, ensuring customers can stay connected when it matters most.

In today’s always-on world, running out of airtime is more than a minor inconvenience. It can mean missed opportunities, disrupted plans, and lost connections, often at the very moment when funds are tight, and options are limited. Quick Airtime Loan was created to solve this problem, offering customers instant access to airtime on credit, directly from their bank. With Quick Airtime Loan, eligible GTBank customers can access from ₦100 and up to ₦10,000 by dialing *737*90#. Available across all major mobile networks in Nigeria, the service will soon expand to include data loans, further strengthening its proposition as a reliable on-demand platform.

For years, the airtime credit market has been dominated by Telcos, where charges for this service are at 15%. GTBank is now changing the narrative by offering a customer-centric, bank-led digital alternative priced at 2.95%. Built on transparency, convenience and affordability, Quick Airtime Loan has the potential to broaden access to airtime, deliver meaningful cost savings for millions of Nigerians, and redefine how financial services show up in everyday life, not just in banking moments.

Commenting on the product launch, Miriam Olusanya, Managing Director of Guaranty Trust Bank Ltd, said: “Quick Airtime Loan reflects GTBank’s continued focus on delivering digital solutions that are relevant, accessible, and built around real customer needs. The solution underscores the power of a connected financial ecosystem, combining GTBank’s digital reach and lending expertise with the capabilities of HabariPay to deliver a smooth, end-to-end experience. By leveraging unique strengths across the Group, we are able to accelerate innovation, strengthen execution, and deliver a more integrated customer experience across all our service channels.”

Importantly, Quick Airtime Loan highlights GTCO’s evolution as a fully diversified financial services group. Leveraging HabariPay’s Squad, the solution reinforces the Group’s ecosystem proposition by bringing together banking, payment technology, and digital channels to deliver intuitive, one-stop experiences for customers.

With this new product launch, Guaranty Trust Bank is extending its legacy of pioneering digital-first solutions that have redefined customer access to financial services across the industry, building on the proven strength of its widely adopted QuickCredit offering and the convenience of the Bank’s iconic *737# USSD Banking platform.

About Guaranty Trust Bank

Guaranty Trust Bank (GTBank) is the flagship banking franchise of GTCO Plc, a leading financial services group with a strong presence across Africa and the United Kingdom. The Bank is widely recognized for its leadership in digital banking, customer experience, and innovative financial solutions that deliver value to individuals, businesses, and communities.

About HabariPay

HabariPay is the payments fintech subsidiary of GTCO Plc, focused on enabling fast, secure, and accessible digital payments for individuals and businesses. By integrating payments and digital technology, HabariPay supports innovative services that make everyday financial interactions simpler and more seamless.

Enquiries:

GTCO

Group Corporate Communication

[email protected]

+234-1-2715227

www.gtcoplc.com

-

celebrity radar - gossips6 months ago

celebrity radar - gossips6 months agoWhy Babangida’s Hilltop Home Became Nigeria’s Political “Mecca”

-

society6 months ago

society6 months agoPower is a Loan, Not a Possession: The Sacred Duty of Planting People

-

society5 months ago

society5 months agoReligion: Africa’s Oldest Weapon of Enslavement and the Forgotten Truth

-

news6 months ago

news6 months agoTHE APPOINTMENT OF WASIU AYINDE BY THE FEDERAL GOVERNMENT AS AN AMBASSADOR SOUNDS EMBARRASSING